SSM Forge orifice

SSM Forge orifice plate is a device used for measuring flow rate. Either a volumetric or mass flow rate may be determined, depending on the calculation associated with it. It uses the same principle , namely Bernoulli’s principle which states that there is a relationship between the pressure of the fluid and the velocity of the fluid. When the velocity increases, the pressure decreases and vice versa.

SSM Forge ‘s orifice plate is a thin plate with a hole in the middle or edge depending on design as per application . It is usually placed in a pipe in which fluid flows mounted between a flanged assembly.

SSM Forge manufactures orifice plate assemblies for various applications. Applications which go for conditions summarised as below :

Type of orifice plate | Reynolds | Application |

Square edge concentric | 7500 onwards | For all applications with clean fluids |

Conical entrance | 80 to 1500 | High viscosity application which requires accuracy at lowest Reynolds , thus effectively getting rid of applications of magnetic and vortex |

Eccentric | 3000 to 12000 | For liquids containing solid particles or for vapours likely to deposit water condensate , also used for bottom flush application |

Quadrant edge | 1500-9000 | Viscous fluids and mostly for Fertiliser and petrochemicals |

Segmental | 5000-20000 | Sedimentation process application |

The different types of orifice plates are:

Concentric

Eccentric

Segmental

Quadrant Edge

SSM Forge made Orifice Performance

Principally, SSM Forge’s orifice plate is a precision instrument. In best circumstances, the inaccuracy of Orifice plates can possibly fall in the range of 0.75-1.5%.

Factors used to calculate performance Orifice plate:

1. Precision in the bore calculations

2. Quality of the installation

3. Condition of the plate itself

4. Orifice area ratio

5. Physical properties of the fluid flow under measurement

6. Permanent Pressure Loss

7. Pipe Length

Various types of orifice assemblies

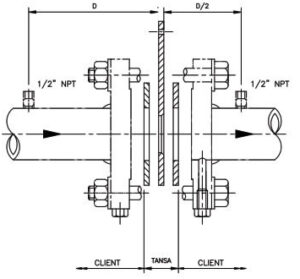

• The weld neck flange assembly is designed to transfer stresses to the pipe, thereby reducing high-stress concentrations at the base of the flange. The pressure tapping is provided through the flange which are at a distance of approximately 20mm to 26 mm from the face of the plate.

• The slip-on flange has a low hub because the pipe slips into the flange prior to the welding. It is welded both from inside and out to provide sufficient strength and prevent leakage. The slip-on flanges are bored slightly larger than the OD of the matching flange

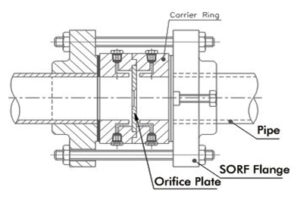

• Orifice assembly with carrier ring and flange union is provided to facilitate pressure tapping, by means of corner tappings. This construction is generally used for lower sizes. Carrier ring assembly is used up to 2” or maybe still higher but only till 300# and if it is used for 600# the size should be reduced and be restricted till 2”

• RTJ assembly for high temperature and pressure: The plate holder assembly is a combination of plate holder and an orifice plate designed for ring tongue joint flanges. The plate holder has a function of holding the orifice plate and also the function as a gasket to prevent leakage of the process fluid. The plate holder has a oval or octagonal ring for mounting between ring tongue joint flanges. This metallic sealing system is applicable to a fluid of high temperature and high pressure. The pressure tapping system normally is of the flange tap type. Orifice plate is screwed to the plate holder. Generally the plate holder is of the softer material like soft iron. The orifice plate is available in standard material such as SS316, 304, 304L, SS316L, PP, Hastealloy , Monel, PTFE , etc depending on applications.

SSMF Restriction orifice plate and its assemblies :

Restriction plate is a different operating principle developed by SSM Forge wherein pressure gradient is developed across while the phenomenon is to keep a no loss flow.

Multistage assemblies

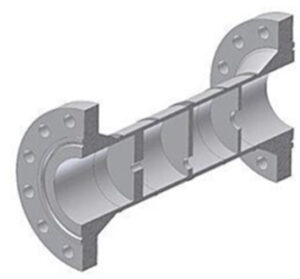

It is a Restriction Assembly where multiple Restriction plates are used to achieve pressure loss.

SSM Forge manufactured multistage orifice assemblies are another type of measuring flow with high differential pressure meters effectively removing cavitation and flashing conditions. It also helps in killing pressure and thus effectively acting as a pressure reducing element. These are basically used to detect flow of fluids, gasses , steam , steam water , acids , alkalies , crudes , high viscous fluids , fluids with solid particles , condensation liquids .

The design is applicable from ½” to 64” of flow measurement.

Applications

• Gas and Liquid Flows

• High Pressure Drops

Prevents

• Cavitation and Flashing in Liquid flows

• Choked flow in gases

• Excessive Noise / Vibration

Restriction orifice plates have traditionally been used to reduce pressures in GAS and LIQUID flows by forcing the flow through a restricted bore.

Where very HIGH PRESSURE DROPS in liquid flows are desired, MULTISTAGE RESTRICTION ORIFICE ASSEMBLIES may be required to achieve the desired pressure drop whilst preventing problems such as CAVITATION, FLASHING and high NOISE and VIBRATION levels.

SSM Forge make Multistage ROs are manufactured from a wide range of materials and are engineered to meet specific project process conditions and requirements. Process connections to existing pipe work can be either standard process flanges or machined ends suitable for butt welding.

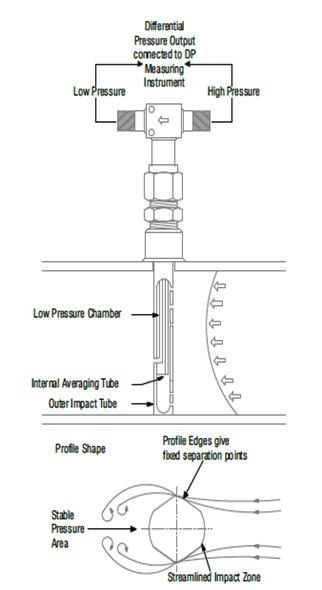

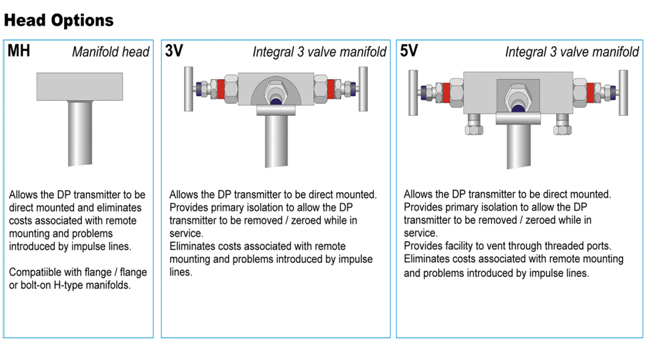

An Averaging Pitot Tube is a primary element is similar to a single point pitot tube used to measure the flow of gas, steam, or liquid in a pipe.

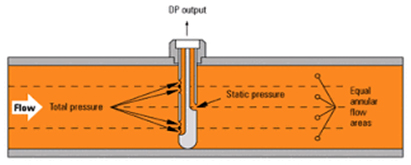

Averaging Pitot tube takes multiple samples across a section of a pipe or duct. In this way, it averages the differential pressures encountered accounting for variations in flow across the section. By averaging the flow velocity across the pipe, averaging pitot tubes are more tolerant of errors bends and valves upstream of the meter. By adding pressure and temperature measurement with modern multivariable differential pressure transmitters we can provide an output signal that is proportional to mass or corrected volumetric flowrate.

SSM Forge make averaging Pitot tubes have the potential to measure two pressures at the same time i.e. impact (dynamic) and static. The static pressure is the operating pressure in the pipe, duct, or the environment, upstream to the Pitot tube. It is measured at right angles to the flow direction. In an Averaging Pitot -static tube, the kinetic energy of the flowing fluid is transformed into potential energy for measurement of fluid flow velocity.

As per the ISO 5167 std and also IEC 60534 for flow conditions and all internationally acclaimed conditions the flow rate recorded in averaging pitot tube.

Construction Standard:

• Engineered and manufactured to stringent routines including BS, ANSI, ASME, ISO and DIN standards

• Welding is carried out by qualified welders to ASME IX and European standards.

• Quality control system is approved to BS EN ISO 9002-1994

• Averaging Pitot Tube are leak tested before dispatch.

• Hydrostatic pressure testing

• Standard material of construction is 316 stainless steel but many other materials are available on request.

Advantages in using Averaging Pitot tube :

1. No moving parts.

2. Easy installation and low pressure loss.

3. Low permanent pressure loss – energy lost with use is minimal.

4. Robust construction – long service life and virtually impossible to wear out.

5. Negligible wear and tear – long term stability with zero drift or degradation.

6. Diamond shaped sensor in forged construction, enables perfect velocity and flow distribution, enabling no erosion on the material on contact with media.

7. With aerodynamic design, enabling, perfect pressure distribution to provide most workable solution against cavitation and flashing conditions of the liquid media and against choking of the gas / vapour media.

8. Cost effective as against orifice assembly, ventury and flow nozzle as the free length space involved with SSM Forge make, is only 2D in upstream and 1D in downstream as compared to higher lengths defined as per beta ratio in ventury orifice and nozzle.

9. Low pressure drop, resulting into most free accurate reading of flow measurement compared to other device.

10. High flow recovery coefficient achieved with averaging ports.

11. Also applicable for bidirectional flow by providing averaging ports on either sides, especially used in gas lines

12. High accuracy